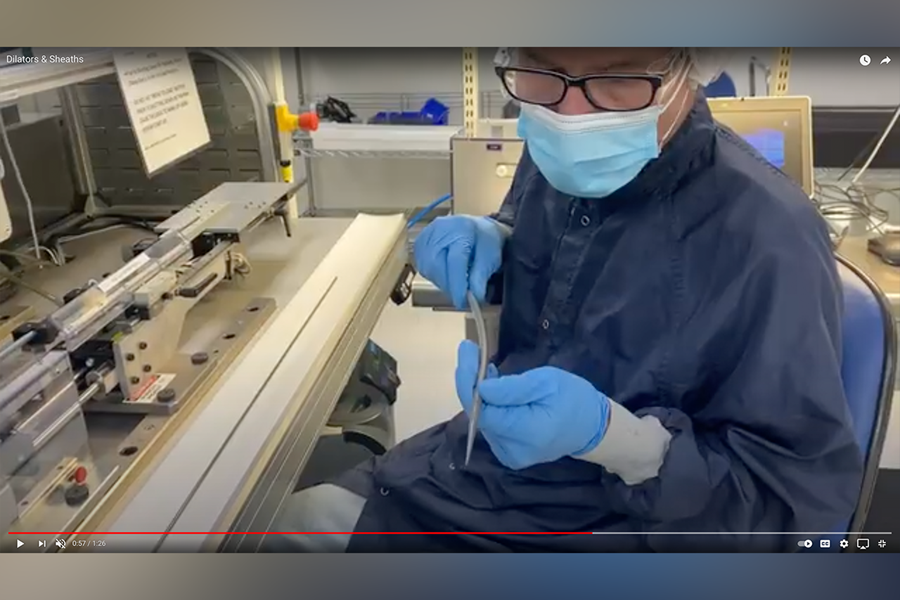

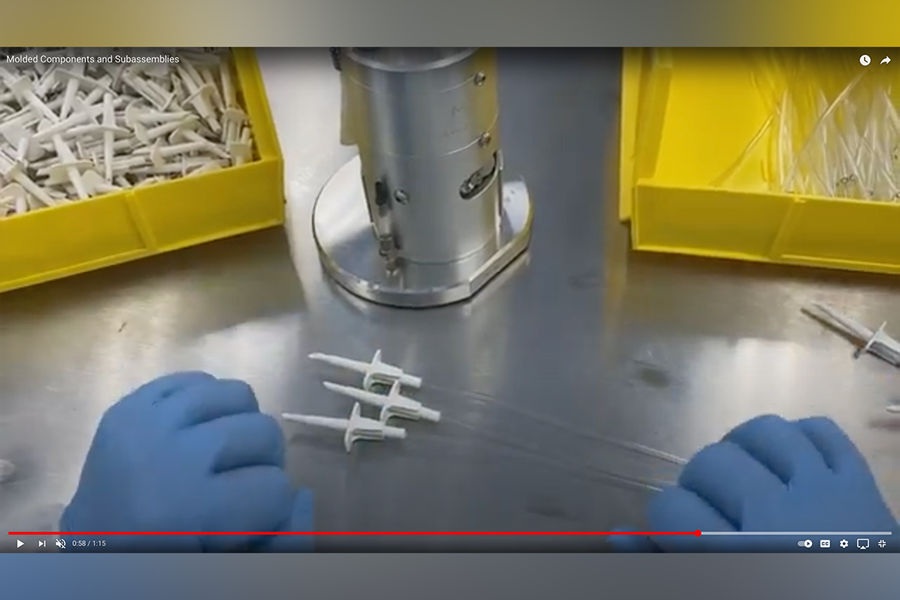

Video

Spectrum Touching Lives

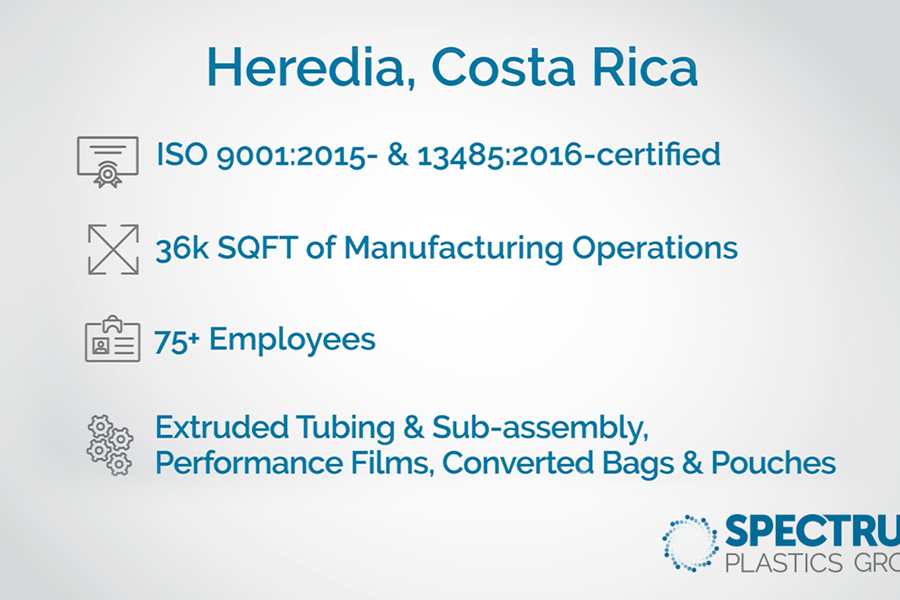

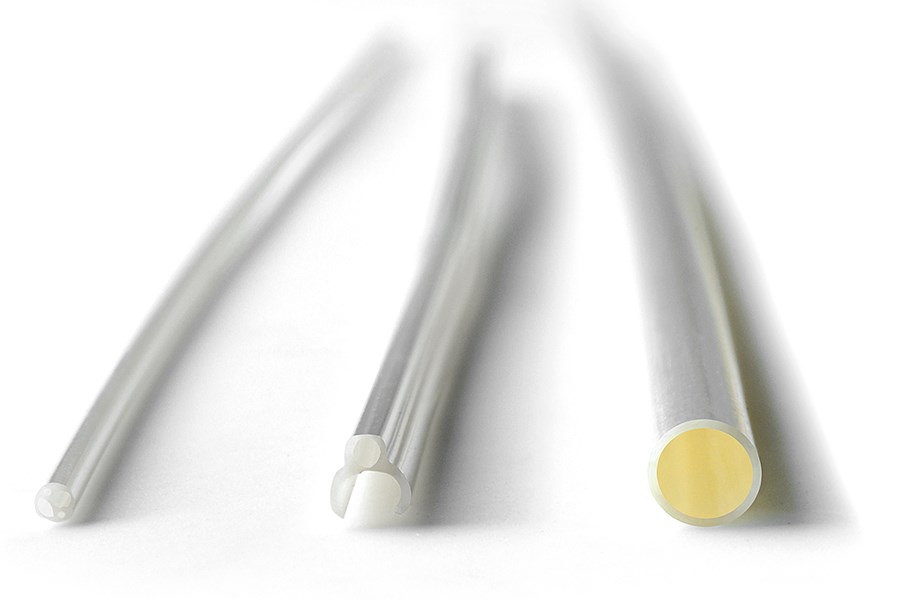

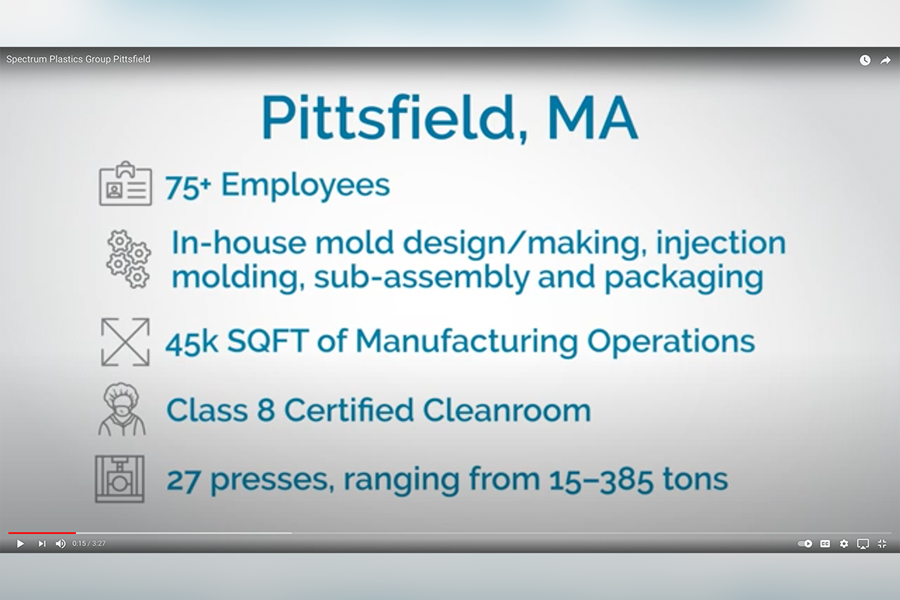

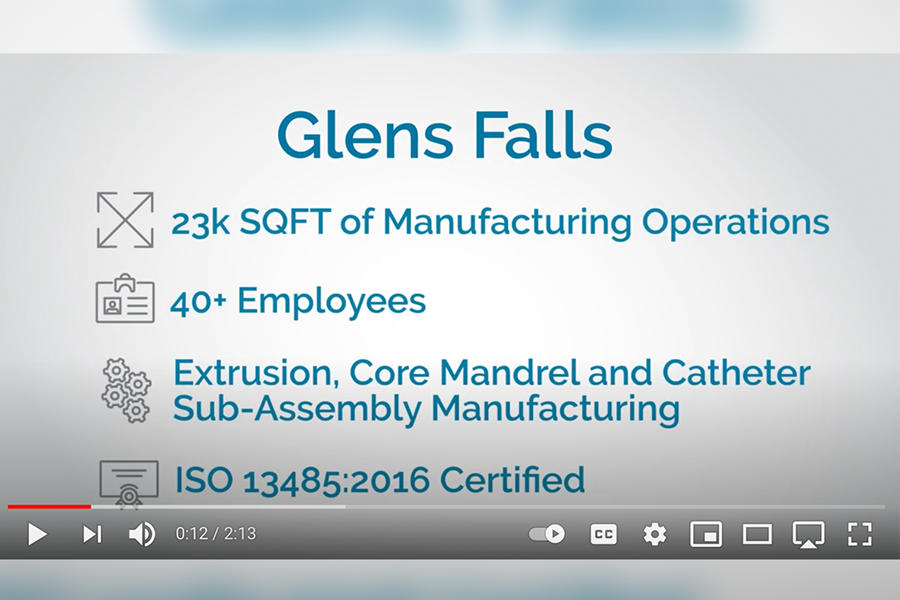

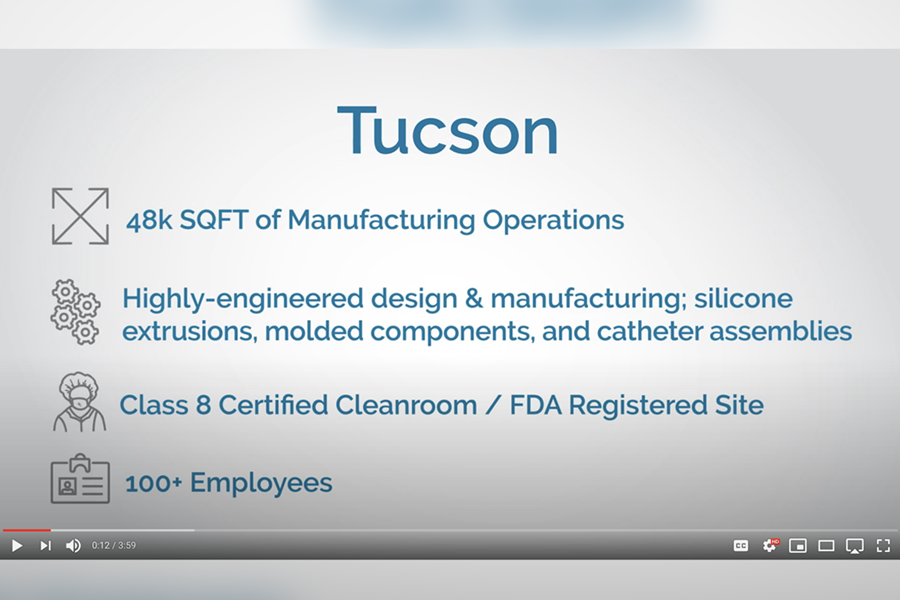

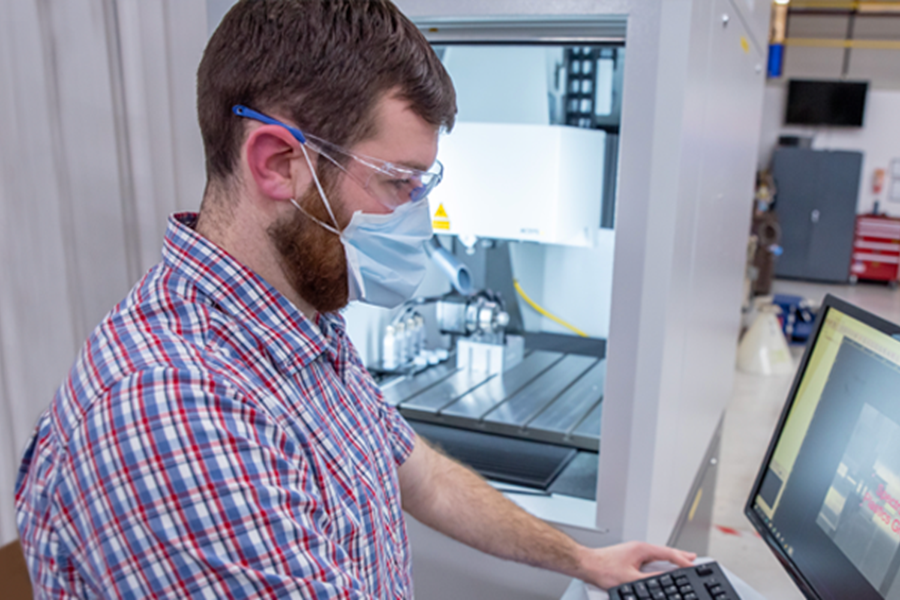

Spectrum has your next-generation solutions for critical healthcare applications. Our purpose-driven mission drives our innovation impacting people’s lives worldwide.